A unique ecosystem for advanced and additive manufacturing technologies to boost innovation and add value to industry

About

CSEM and EPFL are joining forces and expertise to offer Industry the benefits of advanced and additive manufacturing technologies. These fast-growing sectors are essential if we are to move towards a fully sustainable economy. The M2C platform aims to accelerate the adoption of these technologies through the design of lighter, more robust, complex, and accurate components and systems.

Mission & Objectives

From basic and applied research (EPFL) to applied research and technology transfer (CSEM), M2C aims to address critical scientific and technological challenges facing the manufacturing industry. The center will focus on the latest developments in high-precision, advanced and additive manufacturing technologies, while bringing together multiple laboratories from both organizations. These laboratories share common research interests and activities related to the future of manufacturing and its impact on society.

M2C’s objectives follow four axes:

- Provide a platform to catalyze interactions between various academic, institutional, and industrial partners

- Initiate, unite, and coordinate research projects in the field of advanced and additive manufacturing

- Develop new training opportunities, ranging from apprenticeships to doctoral programs

- Ensure efficient technology transfer to industry

Expertise

M2C’s activities are focused on the customization and functionalization of microengineered components and systems. For this purpose, the center develops and offers capabilities in:

Metal additive manufacturing

- Material development & design for AM

- LPBF process development & optimization

- Advanced characterization & qualification

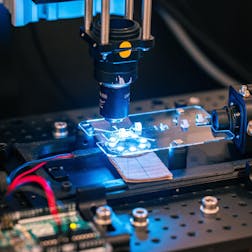

Femtosecond laser processing

- In-situ laser feedback

- Free-form functional integration

- Combining optics with other modalities

Functional materials & systems

- Multi-materials & multi-processing

- Metamaterials for smart systems

- Integrated functions

Latest news

News WP: 2025-11-17 12:00:03

News WP: 2025-11-17 12:00:03

“I would be my own worst student”

Francesco Stellacci likes teaching all kinds of things. With his effective yet unpretentious manner, he won the 2025 best teacher award for the materials science and engineering section. He lists two ingredients in his recipe for success.

EPFL is one of Europe’s most vibrant and cosmopolitan science and technology institutions : students, professors and staff come from over 120 nations. In a dynamic environment, EPFL has both a Swiss and international vocation. It focuses on three missions: teaching, research and innovation. EPFL collaborates with an extensive network of partners including other universities and institutes of technology, secondary schools and colleges, industry and economy, political circles and the general public, with the aim of having a real impact on society.

CSEM is an internationally recognized Swiss innovation center developing disruptive technologies with a high societal impact, which it then transfers to industry. A public-private organization, its mission is to support the innovation activity of Swiss companies and strengthen the economy. CSEM is active in the domains of precision manufacturing, digitalization, and sustainable energy. Daily, CSEM's 550 employees from 44 countries collaborate with leading universities, research institutes, and industrial partners. Headquartered in Neuchâtel, CSEM also has sites in Allschwil, Alpnach, Bern, Landquart and Zurich.